Description

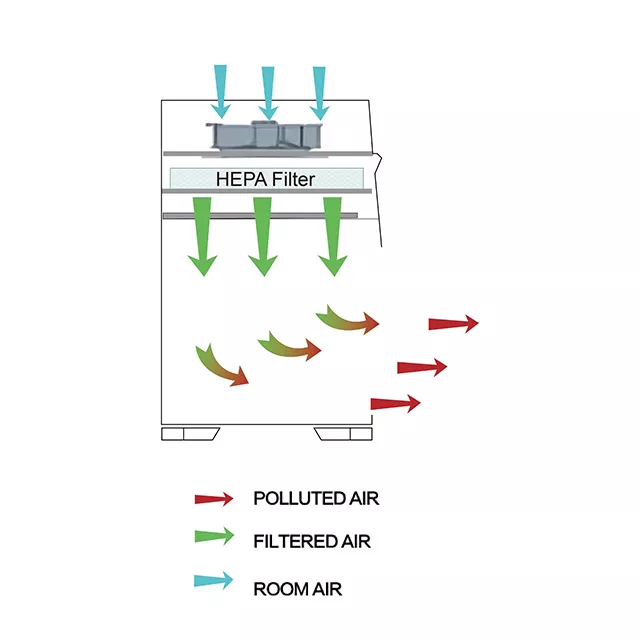

The vertical laminar flow cabinet safeguards samples by directing purified air in a vertical, unidirectional stream across the working zone. This airflow exits the main work chamber uniformly across the entire open front of the cabinet. Additionally, perforations at the back wall of the work zone are incorporated to eliminate air turbulence and prevent the formation of dead air corners, ensuring optimal working conditions within the cabinet.

Vertical Laminar Flow Cabinet Features:

- Control panel is ergonomically positioned at the center and angled downward for easy reach and viewing.

- Work surface is crafted from brushed stainless steel, ensuring easy cleaning and maintenance.

- Utilizing a non-direct light source design, the cabinet effectively reduces operator visual fatigue while maintaining adequate illumination.

- Microprocessor controller features an intuitive interface with an LCD display, providing graphical and digital feedback on the status of each function, including filter and UV lamp life.

Vertical Laminar Flow Cabinet Specifications:

| Model | LCB-V-LP1100 | LCB-V-LP1300 | LCB-V-LP1600 | LCB-V-LP1900 |

| External Size (WxDxH) (mm) | 1050x710x1850 | 1320x710x1850 | 1625x710x1850 | 1930x710x1850 |

| Internal Size (WxDxH)(mm) | 950x615x625 | 1220x615x625 | 1525x615x625 | 1830x615x625 |

| Work Surface Height | 750mm |

| Control System | Display | Microprocessor controller with LCD display, display the operating status of each function |

| Interlock | Front sliding sash interlock with fan and UV lamp |

| Life Indicator | HEPA filter and UV life indicators facilitate a timely replacement plan |

| Airflow System | Airflow Velocity | 0.2~0.5 m/s, speed adjustable |

| Air filtration System | Pre-Filter | 1pcs, Polyester fiber,washable |

| HEPA Filter | 1 pcs, Efficiency: > 99.995% at particle size of 0.3μm |

| Cleanliness Grade | ISO Class 5 (formerly Class 100) |

| Partial air circulation | Perforations at the back wall of the work zone which are designed to eliminate air turbulence and the possibility of dead air corners in the work zone. |

| Cabinet Construction | Main Body | Electro-Galvanized steel with antimicrobial powder coating |

| Work Surface | 304 Stainless steel |

| Front Window | Manual sliding sash: 5 mm UV resistant tempered glass with counter-balance system and ergonomic handle |

| Side window | 5 mm UV resistant tempered glass |

| Electrical System | UV Lamp | 20W×1 | 30W×1 | 30W×1 | 20W×2 |

| With timing function from 0 to 999 minutes, Interlock with front sliding sash. |

| Emission of 253.7 nanometers for best sterilization effect. |

LED Lamp

Consumption | 6.5W×1 | 9.6W×1 | 9.6W×1 | 6.5W×2 |

| 155W | 285W | 285W | 300W |

| Not include socket loading power consumption |

| Power Supply | AC220V±10%, 50/60HZ; 110V±10%, 60Hz |

| Illumination | ≥900Lux |

| Sound Emission | ≤65dB(A) |

| Standard Accessory | 1. Base Stand; 2. LED Lamp; 3. UV Lamp; 4. Waterproof Socket×2 |

| Optional Accessory | Gas Tap |

| Gross Weight (kg) | 225 | 255 | 285 | 330 |

| Shipping Size (W×D×H)(mm) | 1190x990x1325 | 1460x990x1325 | 1765x990x1325 | 2070x990x1325 |

| Shipping Volume (m3) | 1.56 | 1.92 | 2.3 | 2.7 |

Vertical Laminar Flow Cabinet Detail and Packing:

The working area of the vertical laminar flow cabinet is made of 304 stainless steel, which guarantees the material’s resistance to corrosion and cleaning. The manual sliding door is made of 5 mm UV-resistant toughened glass with a counterbalance system and ergonomically designed handles for the operator’s convenience.

The side windows are made of 5 mm UV-resistant toughened glass, ensuring reliable visibility and UV resistance.

Clear display makes it easy to monitor the device’s operating status and parameter settings

The vertical laminar flow cabinet is fully protected and securely installed during transport. The laminar flow cabinet is surrounded by dense packing material to prevent collision and vibration during transport.

We provide sea freight, air freight, land freight, express service, accept EXW, FCA, FAS, FOB, CFR, CIF, CPT, CIP, DAF, DES, DEQ, DDU, DDP and other trade terms.

How a vertical laminar flow cabinet works?

A vertical laminar flow cabinet works by drawing air through a HEPA filter, which removes contaminants, and then directing this clean air downward in a vertical laminar flow pattern onto the work surface, creating a sterile environment for tasks such as tissue culture, sample preparation, or pharmaceutical compounding.

WHY Labpeak

- 18 Months Limited Warranty

- Help meet ISO, FDA, CE quality assurance guidelines

- 1-2 Days Handling and 7-30 Days Shipping

Get Social